ABOUT US

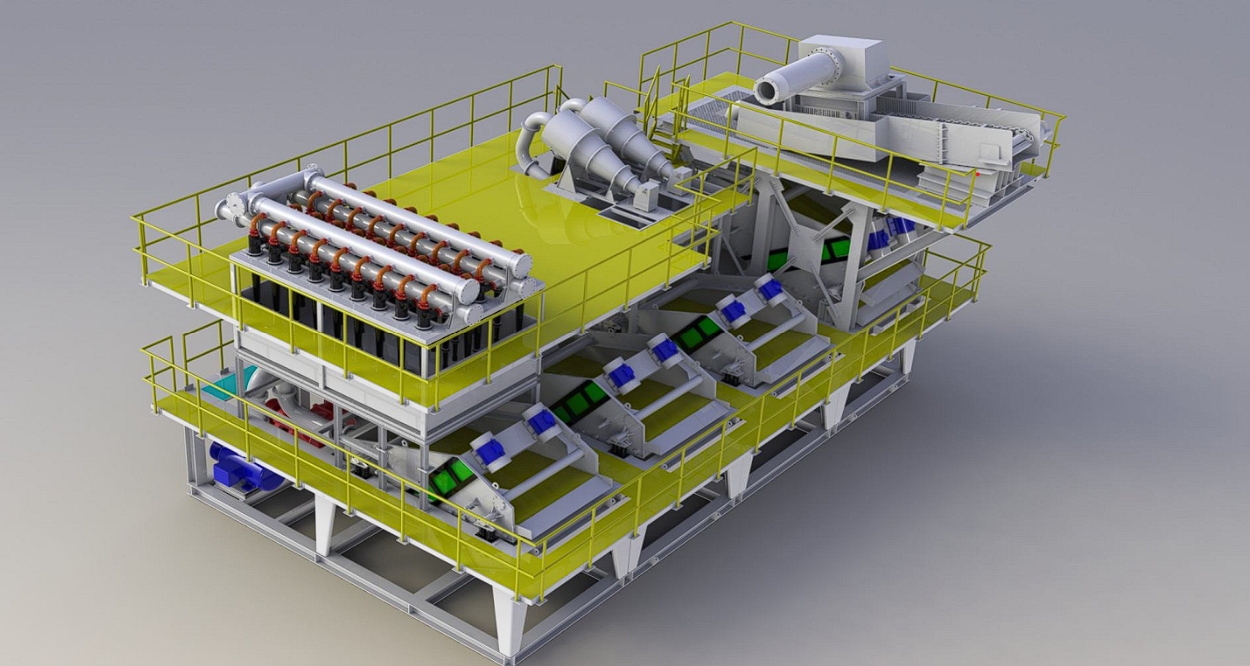

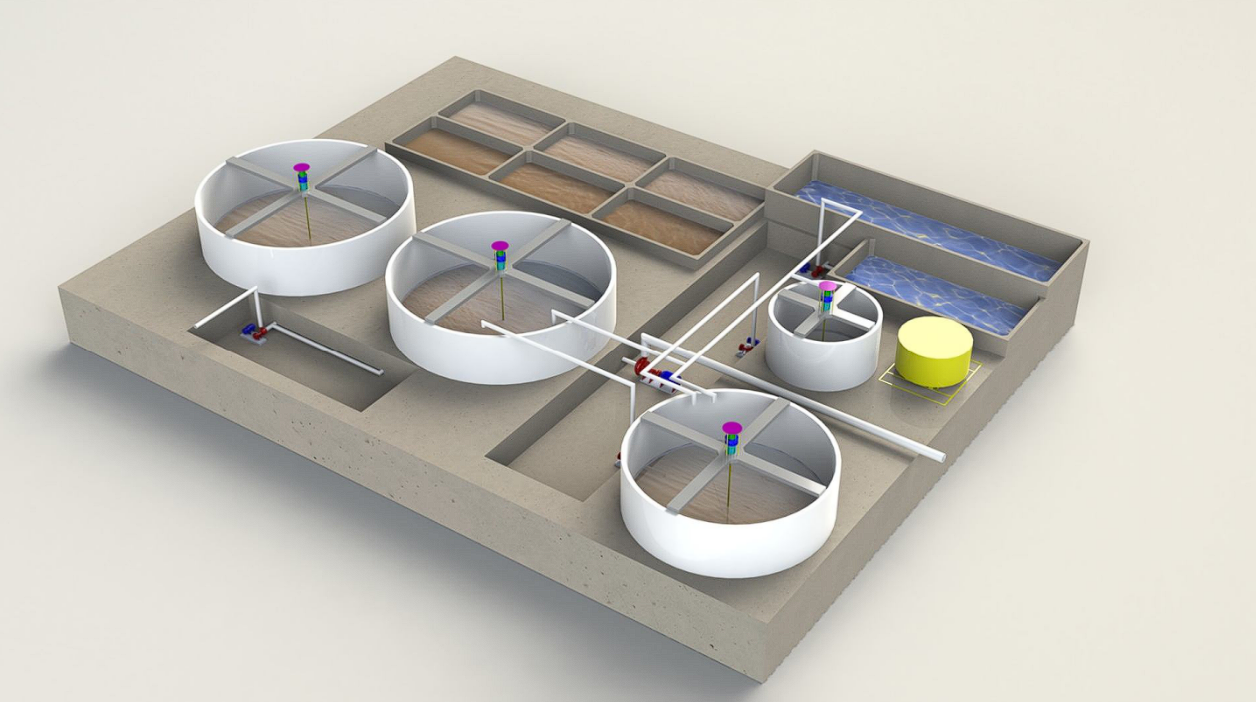

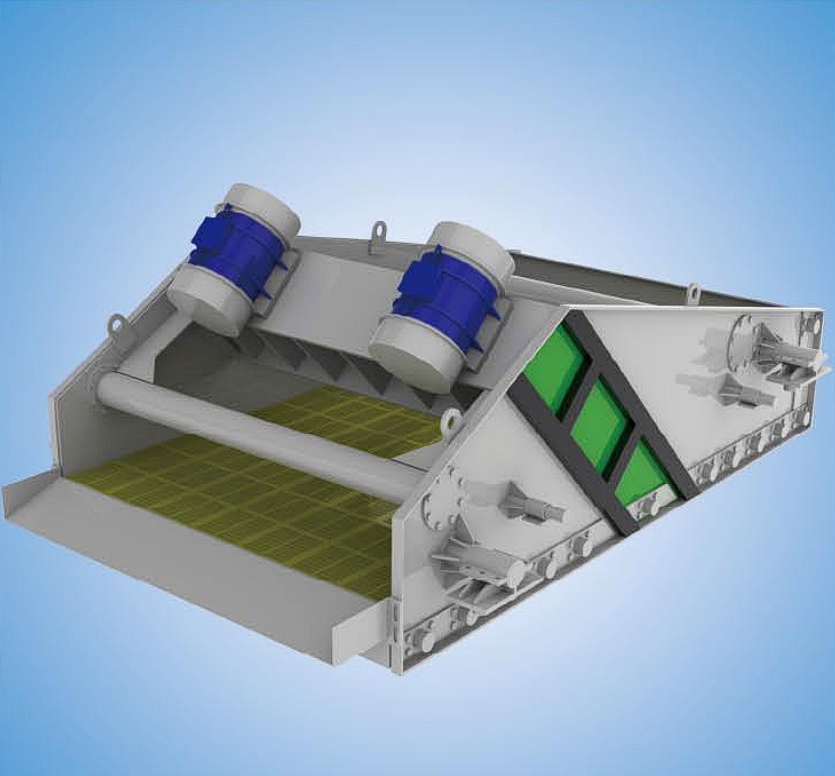

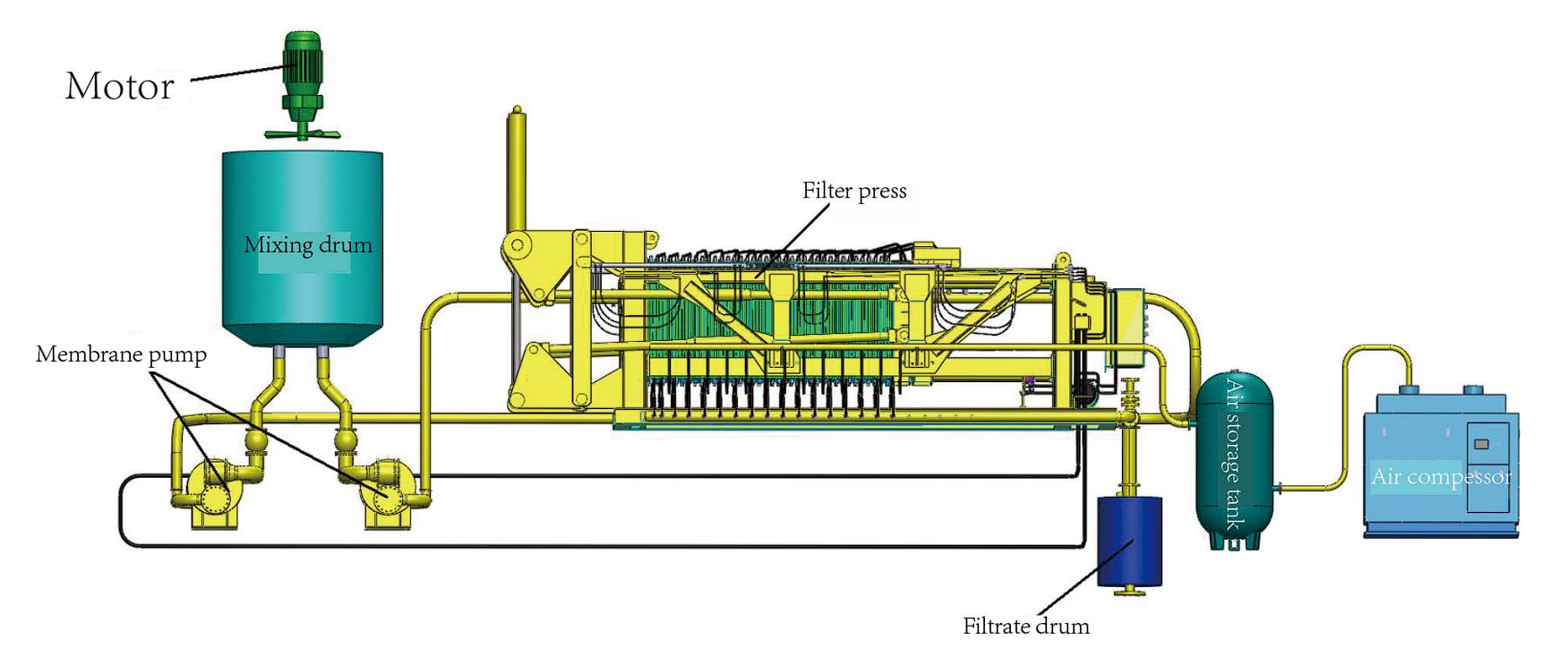

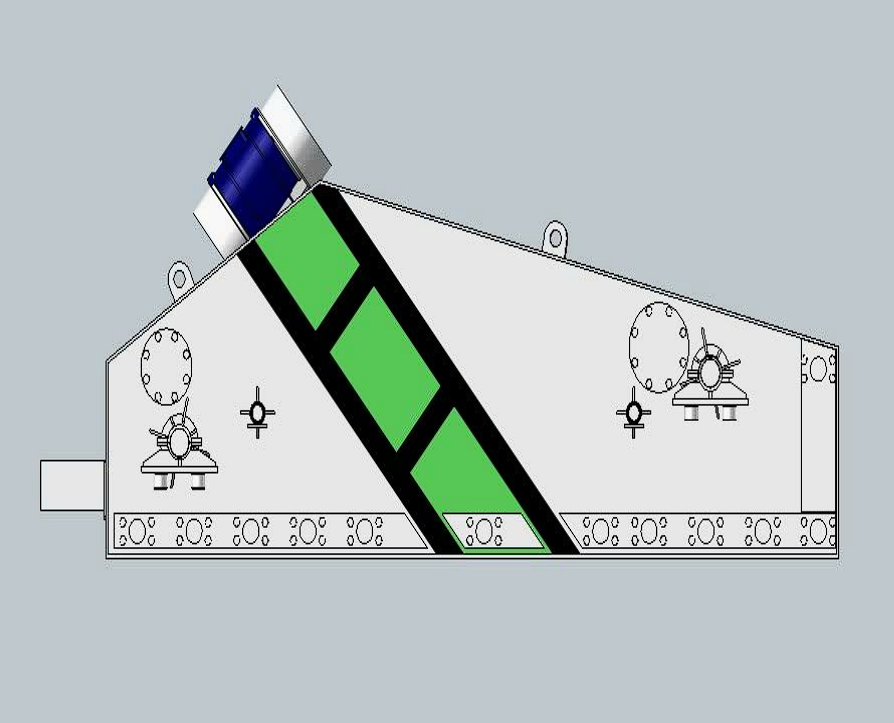

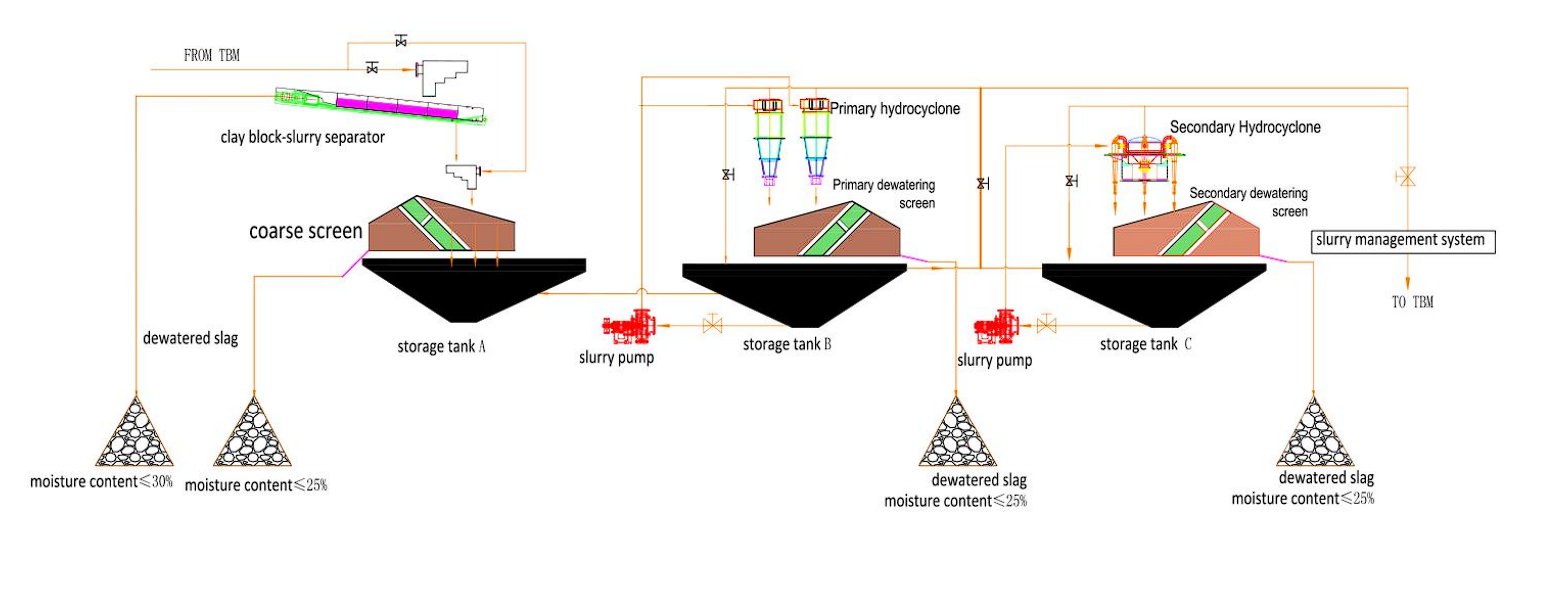

Comex India is a professional manufacturer which design, develop, and manufacture Slurry Separation Plant for slurry TBM and tunnels, micro-tunnels projects

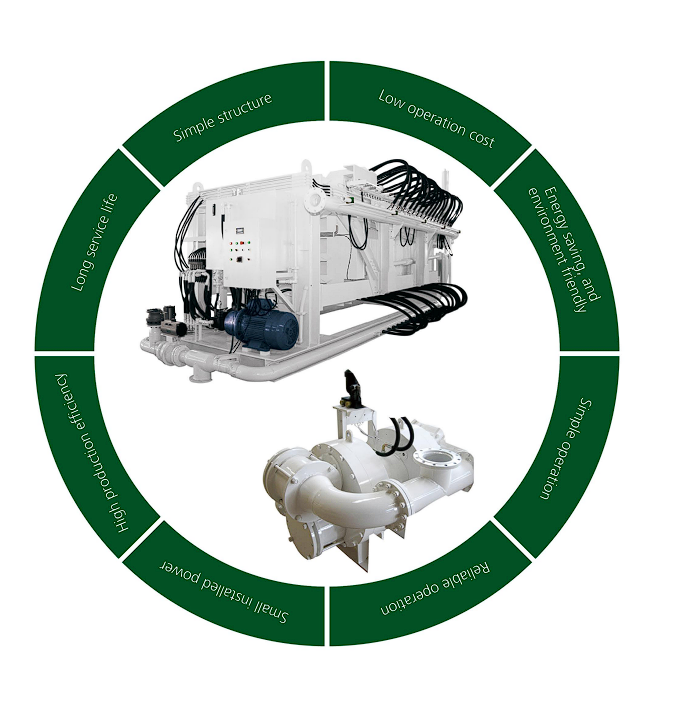

Comex India is the Indian partner of Comex(BJ) Mechanical & Electronic Equipment Co. Ltd. One stop solution of complete slurry handling needs from design to commissioning. We are specialized manufacturer of filter presses, having obtained both ISO 9001:2000 quality certificate and ISO 14001:2004 environment certificate. Comex has researched and developed systematic equipments applicable to solid-liquid filtration field.

Quality Sales

Widely used in industries

Waste water treatment and tunnel shield

Low operation cost

Since

2020

Vision

To be the premier provider of comprehensive solid-liquid separation systems, driven by integrity, innovation.

Value

Quality lays our foundation, and service shapes our future. With a pioneering spirit, proactive approach, and commitment to innovation, we strive for excellence in every aspect.

Mission

To deliver best proven technology equipment, quality and service for industrial growth an environment protection.